Welcome to the Vintage Cellars Wine Cellar Cooling Units Ultimate Guide. This is a complete guide to everything you ever wanted to know about Wine Cellar Cooling Units. This is a living document and we will update this on a regular basis to improve information and update with new information.

Check out our Wine Cooling Units Buyer's Guide to help you choose the perfect wine cooling unit for your custom wine cellar.

For your convenience we have provided a table of contents to help you find information of interest. Enjoy!

Wine Cellar Cooling Units Ultimate Guide Table of Contents

First... Wine Storage Basics

History and tradition have demonstrated that wines are best stored and aged in an environment that has three qualities:

- Coolness – around 55°F

- Dampness – humidity between 50% and 70%

- Darkness – protection from direct sunlight (UV)

Back to Top

Wine Storage History

In the Beginning... Early History of Wine Storage

Before modern technology coolness and dampness were typically found underground, in a cave or a cellar. A search for the beginnings of wine storage takes us back to the origins of wine itself. Archeologists have found evidence of the first cultivation of vines for wine around 6,000 BCE in the mountains between the Caspian and the Black Sea. From these regions, vine growing and winemaking travelled westwards, becoming an intrinsic part of all the ancient Mediterranean cultures.

In 2008, Armenian PhD student and archeologist Diana Zardaryan of the country’s Institute of Archaeology discovered the earliest known shoe at the Areni-1 Cave. In January 2011, the earliest known winery in the world was uncovered in the cave. Later, in 2011, the discovery of a straw skirt dating to 3,900 years BCE was reported. In 2009, the oldest humanoid brain was discovered in the cave.

The journey from then to now goes by way of ancient Egyptian burial rituals, underground Roman tombs and medieval stone basements repurposed as cellars, to old mining tunnels used by French Champagne makers in the 17th Century.

Ancient Wine Jars Discovered in Egyptian Tomb

In the tomb of Queen Meret-Neith, possibly Egypt's first female pharaoh, archaeologists found hundreds of 5,000-year-old wine jars. Some still contained organic remnants, offering valuable information about early wine production and trade in the Mediterranean and North Africa.

1,900-Year-Old Winery Unearthed in Rhône Valley

In Laveyron, France, archaeologists discovered a Roman-era winery dating back to the 1st century CE. The site included fermentation basins, storage cellars, and evidence of large-scale production, highlighting the significance of viticulture in the region during ancient times.

Lavish Roman Winery Discovered at Villa of the Quintilii

Excavations near Rome revealed an opulent 3rd-century CE winery at the Villa of the Quintilii. This wine production facility featured marble-lined wine presses, wine storage, and decorative fountains, indicating that wine production was not only functional but also a display of wealth and status among the Roman elite.

Medieval Stone Wine Cellar: Hospices de Strasbourg, France

The Hospices de Strasbourg houses one of the most remarkable medieval wine cellars in Europe. Established in the 14th century, this cellar is renowned for containing a barrel of white Alsace wine dating back to 1472, making it one of the oldest known wines still in existence. Over the centuries, this wine has been tasted sparingly, including a notable occasion in 1944 by General Philippe Leclerc during the liberation of Strasbourg. The cellar's enduring structure and the preservation of its contents offer a fascinating glimpse into medieval winemaking and storage techniques.

Medieval Mining Tunnels Transformed into Wine Cellars in Reims, France

In Reims, France, extensive chalk mining tunnels known as "crayères" were excavated by the Romans around 80 B.C. These subterranean spaces were later rediscovered and repurposed by Champagne producers in the 17th century for aging their wines. The crayères provided ideal conditions—consistent cool temperatures, high humidity, and protection from light and vibrations—essential for the fermentation and maturation of Champagne. Notably, the renowned Champagne house Ruinart, established in 1729, utilized these ancient chalk caves for wine storage, a practice that continues to this day. The historical significance and unique architecture of these cellars have earned them recognition as a UNESCO World Heritage site.

Modern History of Wine Cellars

It wasn’t until the development of mechanical refrigeration in the mid-to-late 1800’s that the beneficial natural properties of such cellars could be reproduced artificially and the era of domestic and commercial cooling technology began.

Now, with sophisticated refrigeration equipment and modern building techniques, it is possible to recreate these same conditions in virtually any home or business.

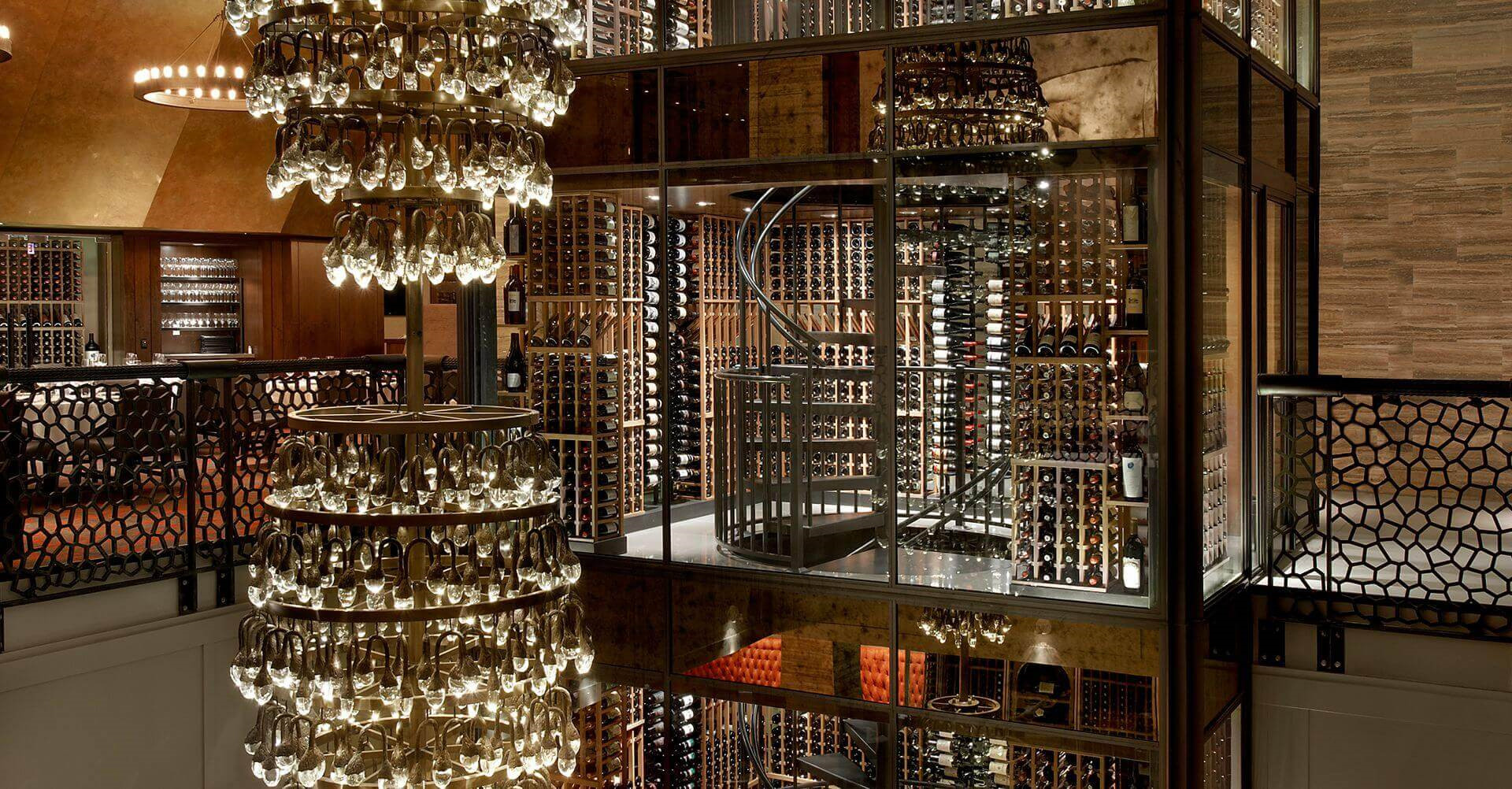

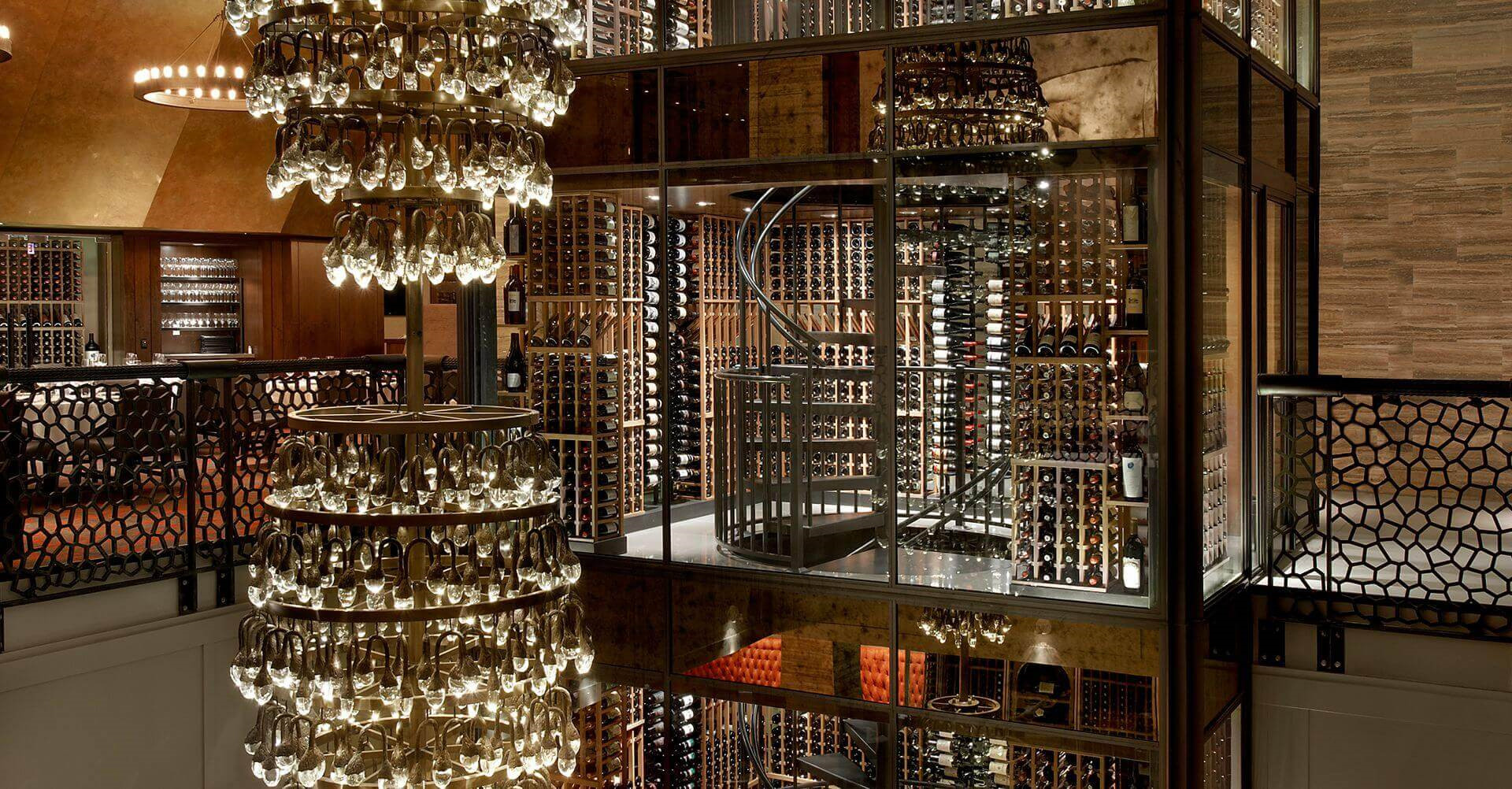

Vintage Cellars collaborated with ZipCo Wine Cellar Services on this extremely complex four-story, glass-enclosed, showpiece custom wine cellar at the center of Del Frisco’s Double Eagle Steakhouse in Chicago, Illinois.

Vintage Cellars collaborated with ZipCo Wine Cellar Services on this extremely complex four-story, glass-enclosed, showpiece custom wine cellar at the center of Del Frisco’s Double Eagle Steakhouse in Chicago, Illinois.

This is not just a question of optimal storage as with any perishable product. Wine can actually improve over time, so proper cellar conditions are doubly important.

Back to Top

How Does a Wine Cellar Work?

Because a stable cool temperature is the crucial factor in wine storage, it is helpful to know how a wine cellar cooling unit achieves this goal. Modern refrigeration is based on a simple principle – that when a liquid evaporates it causes cooling. We all know this on a very personal level because that’s how perspiration works! When we sweat the evaporation of moisture on the surface of our skin has a cooling effect.

First, let’s cover the basics of a wine cellar.

Components / Features of a Modern Wine Cellar

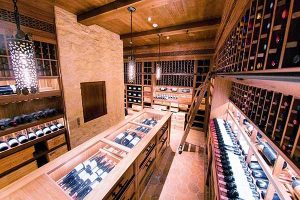

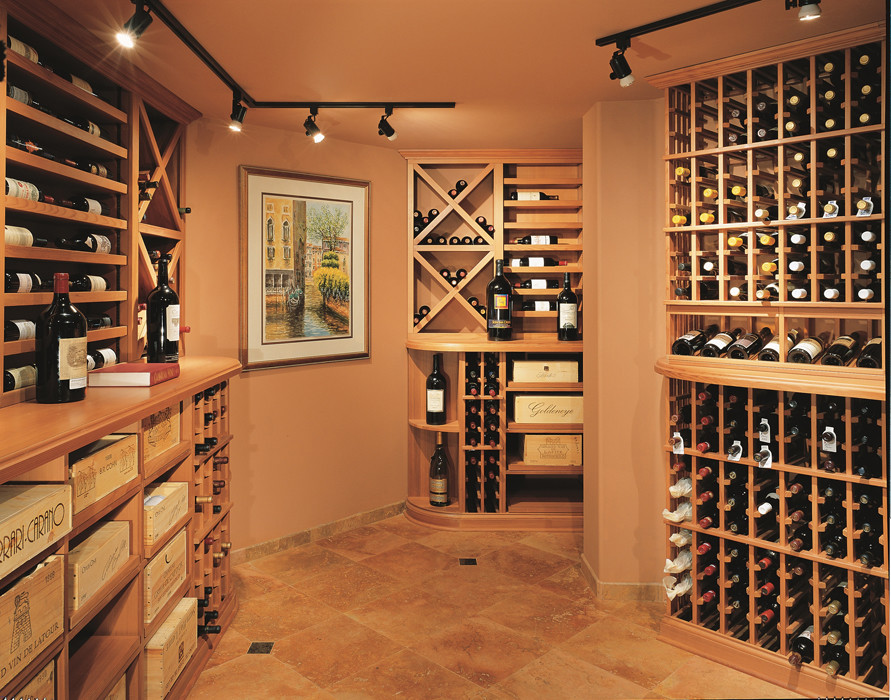

In addition to the wine cellar cooling unit itself, there are a number of factors to consider when designing and building a wine cellar. For more detailed descriptions of the of custom wine cellars, see our Custom Wine Cellars Portfolio.

Vapor Barrier / Insulation / Walls

The Vapor Barrier, Insulation, and Walls create the exterior of the wine cellar and keep outside elements from disrupting environmental factors within the wine storage space.

Wine Cellar Racking

Wine cellar racks hold wine bottles in an organized and efficient manner. Often purchased as wine racking kits and sometimes custom built, wine storage racking holds wine bottles of various sizes, available in many configurations and styles.

Lighting

Decorative lighting plays a large role in the visual aesthetics of your cellar.

Flooring

Flooring is another feature that plays a large role in the visual aesthetics of your wine cellar. It is also important to choose materials suitable for a cool, somewhat damp environment. For instance the walls, the floor must be well insulated.

Doors

The choice of door can be important as it is most likely your guests’ first impression of your custom wine cellar. Again, insulation is a vital factor to consider even with the door to your cellar.

See examples of custom door designs

Glass

Glass walls can be used instead of traditional walls or doors and can turn your wine cellar into a visual centerpiece of your home.

Click here to see Glass Enclosed Wine Cellars

Thermostat / Monitoring

Various devices can be used to monitor the temperature and humidity in your wine cellar. Monitoring the environment of your wine cellar is essential to ensuring conditions remain ideal for the aging of your wine. Temperature, fire, and power are all important factors to monitor.

An example of a thermostat for modern wine cellars is the WhisperKOOL 24 Volt Thermostat Conversion kit, pictured to here.

Power / Backup Power

With all the modern technology and equipment that is used in wine cellars, power and backup power are an essential factor to consider in preserving optimal wine storage conditions.

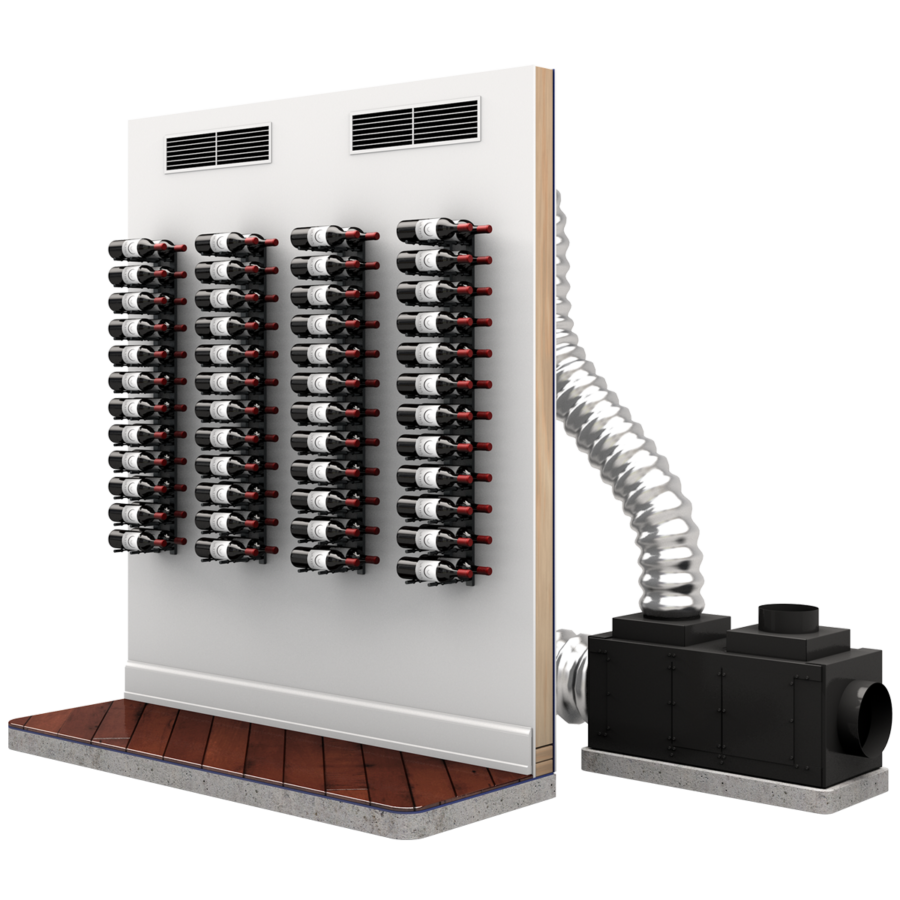

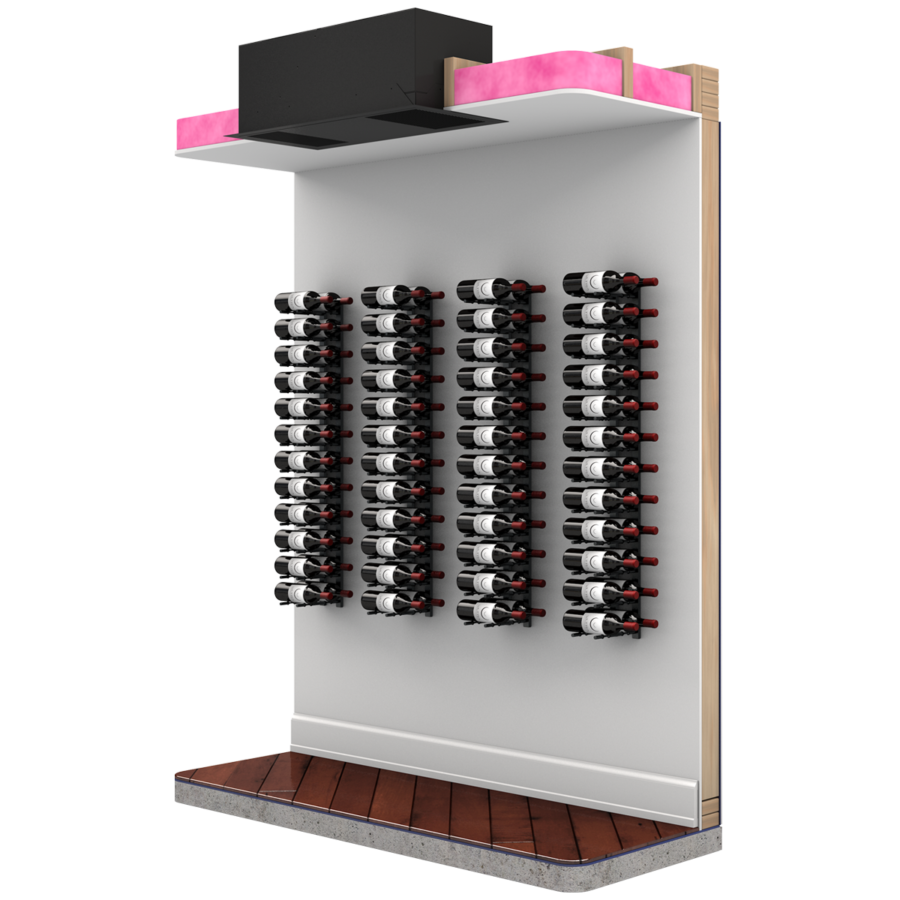

Ducting

As with a domestic HVAC system, ducting is tubing or piping used in some cooling unit configurations to move air to and from the cellar.

Wine Guardian offers a Wine Guardian Combo Duct Kit for its ducted wine cellar cooling unit.

Placement

Where the custom wine cellar is placed in your home or building makes a big difference in the requirements and design of your wine cellar. The configuration of your cellar can be affected by where the sun hits your home, other rooms around your wine storage space, whether your space is under or above ground, and more.

Back to Top

What do Wine Cellar Cooling Units do?

A wine cellar cooling unit creates the two conditions required for optimal wine storage and aging of wine:

- Coolness – around 55°F

- Dampness – humidity between 50% and 70%

Coolness

Research has shown that an 18°F increase from the 55°F baseline doubles the rate of chemical reactions in wine over time. If these chemical reactions age the wine, then why not simply increase the temperature and get a decade's worth of flavor complexity in a few years? Unfortunately, there are no such shortcuts.

A stable temperature of 55° is the perfect environment to foster the chemical reactions that help create fine wine, and at the same time it's too cold to allow the formation of other undesirable reactions that can give a wine unwanted aromas and flavors. Even a short exposure to extreme temperatures can trigger such reactions and spoil the wine. Wine cellar cooling systems are designed to maintain that ideal temperature.

Dampness

A humidity between 50% and 70% is ideal for aging wine. Not enough humidity, and the cork will dry out and crack allowing oxygen-rich air to enter the bottle and oxidation turns wine sour. An environment that’s too humid can cause mold to form on the cork, possibly contaminating the wine. Typically, a wine cellar cooling unit helps keep humidity at desirable levels, but you can also add a stand-alone humidifier if needed.

The job of the wine cellar cooling unit is to push in cool air and remove warmer air from the wine cellar, while at the same time keeping the air between 50% and 70% humidity.

The job of the wine cellar cooling unit is to push in cool air and remove warmer air from the wine cellar, while at the same time keeping the air between 50% and 70% humidity.

Back to Top

How Modern Wine Cellar Cooling Units Operate

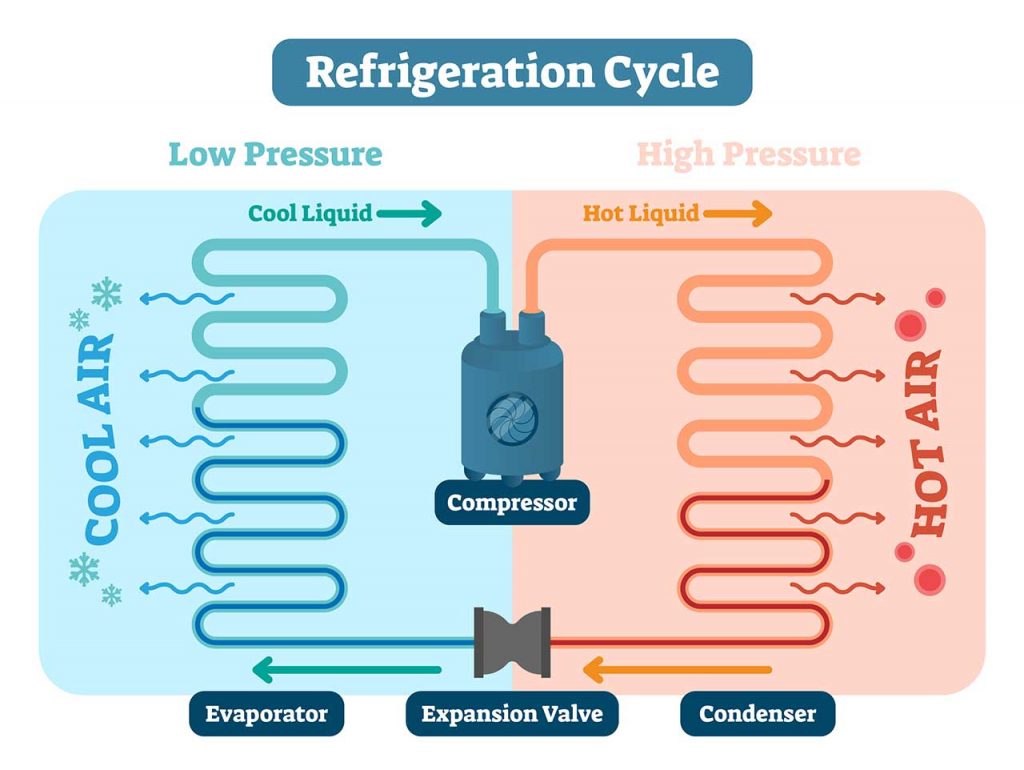

The Refrigeration Cycle

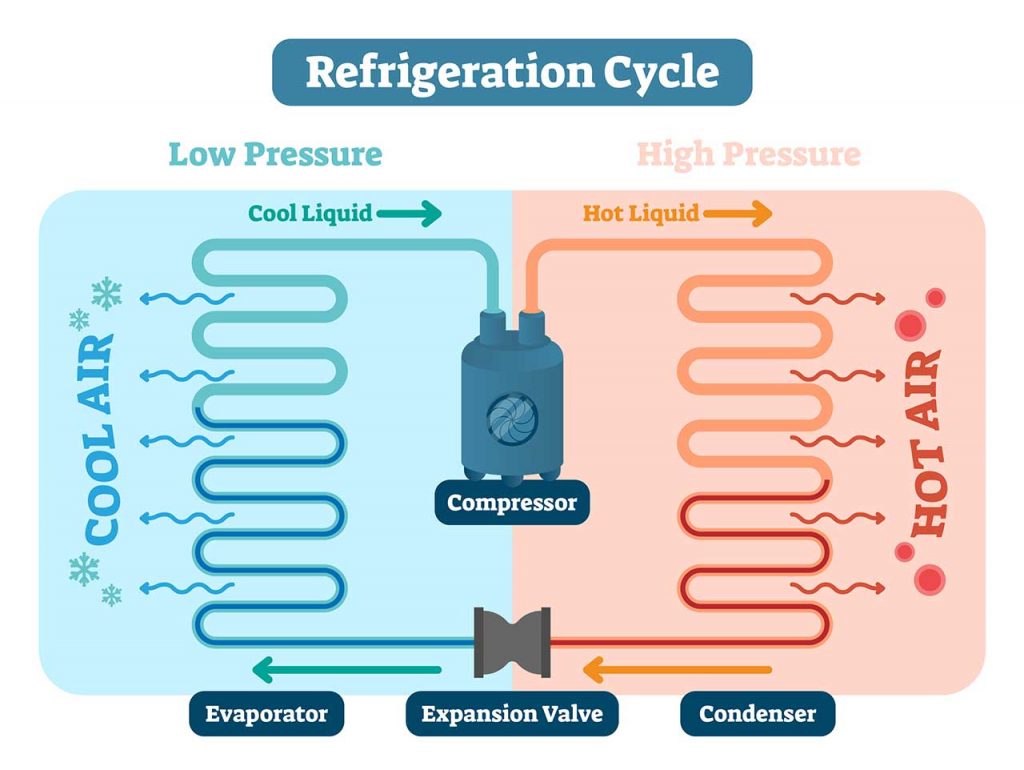

The refrigeration cycle involves the movement of a refrigerant through 4 stages with the goal of maintaining the ideal cool temperature in a wine cellar.

- The refrigerant flows into the Compressor where it is compressed and pressurized. Before going into the compressor, the refrigerant is a hot gas.

- The refrigerant is then pushed (the compressor also acts as a pump) to the Condenser, which turns the vapor into liquid and absorbs some of the heat.

- The refrigerant then proceeds to the Expansion Valve where it expands, losing pressure and heat. The refrigerant coming out of the expansion valve is cold due to the loss of pressure.

- Next it enters the Evaporator Coil in a liquid state where the exchange of heat takes place, creating cooling. The evaporator coil is what actually makes the inside of the wine cellar cold.

- As the gas cools down, it absorbs the heat, which turns it into a gas. The gas is then pushed back into the Compressor where the cycle repeats.

The refrigeration cycle that happens in a wine cellar cooling unit is the same as what happens in most air conditioning units.

The refrigeration cycle that happens in a wine cellar cooling unit is the same as what happens in most air conditioning units.

The compressor unit has a fresh air intake and hot air exhaust, while the evaporator coil delivers the cold air into the cellar and warmer air is removed through a return. Because warm air rises, the cool air is always delivered at a low point in the cellar while warmer air is removed at the top of the cellar. This is where the cellar’s temperature is monitored by a thermostat that controls the system to maintain a consistent temperature of 55°-57° F.

Wine cellar cooling units cool the air slowly and retain moisture, in contrast to air conditioners that are designed to cool air quickly and in doing so tend to dry out the air.

Cooling units create some condensation as a result of temperature changes. This water is collected and removed by a drip line system that usually ties into existing plumbing.

During the refrigeration cycle, a build-up of ice around the evaporator may also occur. Both commercial fridges and freezers address this build-up with some form of defrost system.

Back to Top

History of Wine Cellar Cooling Units

Wine Cellar Cooling Unit Ancestor: Air Conditioners

The history of wine cellar cooling units is tied to the history of air conditioners. Wine cellar cooling units are similar to air conditioners with the primary difference being that wine cellar cooling units cool the air gradually in order to maintain humidity in the wine storage space. On to the history.

Like most important breakthroughs, modern commercial and residential air conditioning technology is a result of a series of advances made by scientists and inventors who challenged themselves to come up with creative solutions to problems of the day.

Icyball is a name given to two early refrigerators, one made by Australian Sir Edward Hallstrom in 1923, and the other design patented by David Forbes Keith of Toronto (filed 1927, granted 1929), and manufactured by American Powel Crosley Jr., who bought the rights to the device.

Air conditioners were first invented in 1851. In the early 1900s, several advances were made to the early model by introducing electricity. Business started using air conditioners to cool air in commercial buildings. The engineering of air conditioners was simplified to make them easier to build and more reliable. Non flammable refrigerating fluids were invented, making air conditioners safer and different types of air conditioners were developed for different types of rooms. By the mid 1900s, window air conditioners were available to every household and being sold across the United States.

There was some additional development to the efficiency of air conditioners in 1975, however there was not much change to the overall technology over those years. In the 1990s government regulations were enacted as the environmental damage of Chlorofluorocarbons (CFCs) was discovered. Throughout the 1990s and into present day, air conditioner technology has advanced, further improving the efficiency through better engineering and modern technologies such as microchips, better materials and coatings, and advancements in environmentally friendly refrigerating fluids.

First machine creates ice using a compressor

Dr. John Gorrie of Florida designs a machine that creates ice using a compressor powered by horse, water, wind-driven sails or steam. He successfully demonstrates the ice-making machine in 1848 and is granted the U.S. patent for it in 1851.

First modern electrical air conditioning

Willis Carrier invents first modern electrical air conditioning unit as a way to solve a moisture problem for a publishing company.

American public is exposed to comfort cooling

At the St. Louis World's Fair, organizers use mechanical refrigeration to cool the Missouri State Building, marking the first time the American public is exposed to the concept of comfort cooling.

Changing air of textile factories

Textile mill owner Stuart W. Cramer of North Carolina uses the term "air conditioning" in a patent claim he files to describe his technique for controlling the humidity and changing the air of textile factories.

"Air conditioning" in a textbook

G.B. Wilson becomes the first person to use the term "air conditioning" a textbook.

Breakthrough lowers cost of large-scale air conditioners

To help improve the performance and reduce the cost of air conditioners, Carrier invents the centrifugal chiller, which has fewer moving parts and less compressor stages than existing units. The breakthrough system increases the reliability and lowers the cost of large-scale air conditioners, greatly expanding their use throughout the country.

First non-flammable refrigerating fluids

Thomas Midgley, Albert Henne and Robert McNary of General Motors synthesize chlorofluorocarbon (CFC) refrigerants for Frigidaire. The chemicals are the world's first non-flammable refrigerating fluids, greatly improving the safety of air conditioners. Decades later, the chemicals are linked to ozone depletion.

New split-system room cooler

Building off refrigeration technology, Frigidaire introduces a new split-system room cooler to the marketplace in 1929. General Electric's Frank Faust improves on this design, developing a self-contained room cooler. The company produces 32 similar prototypes from 1930 to 1931.

Window ledge air conditioning unit patent

Inventors H.H. Schultz and J.Q. Sherman file a patent for an air conditioning unit that can be placed on a window ledge. The units hit the market in 1932 but are not widely purchased due to high cost. Also in 1931, Frigidaire begins marketing year-round, central air conditioning systems for homes.

Compact, inexpensive window air conditioners

Engineer Henry Galson develops compact, inexpensive window air conditioners and sets up production lines for several manufacturers. By 1947, 43,000 of these types of units are sold in the United States.

Advances in air conditioning technologies

Oak Ridge National Laboratory develops the first version of the Heat Pump Design Model, a hardware-based steady-state vapor-compression equipment design tool that helps industry create more energy efficient and cost effective air conditioning technologies.

The Clean Air Act amended for CFCs

The Clean Air Act is amended to include new measures to phase out CFCs and make air conditioners and other cooling technologies more environmentally friendly.

Hydrofluorocarbon (HFC) gains popularity

As CFCs are phased out due to ozone-damaging chemicals, R-134a refrigerant -- a hydrofluorocarbon (HFC) -- gains popularity. While HFCs don’t destroy the ozone, they are strong greenhouse gases.

Energy Department sets efficiency standards

Energy Department sets efficiency standards for residential central air conditioners and heat pumps, which is estimated to result in $29 billion in energy savings from 1993 to 2023 as a result of improved air conditioning technologies.

R-410a as the leading refrigerant replacement

By the late 1990s, Oak Ridge National Laboratory's Heat Pump Design Model is used for product design by companies representing about 30 percent of the market for new air conditioners and heat pumps. In the early 2000s, Allied Signal (now Honeywell) helps establish R-410a as the leading refrigerant replacement in air conditioners in part by using the model to demonstrate the chemical also improves energy efficiency.

New requirements are set for manufacturers

New requirements are set for manufacturers of central air conditioners and heat pumps. The standards are expected to avoid more than 369 million metric tons of carbon dioxide emissions, equivalent to the annual greenhouse gas emissions of about 72.4 million automobiles.

Advances in non-vapor compression technologies

The Energy Department announces new projects advancing non-vapor compression technologies that don’t require refrigerants, representing a seismic shift for the industry.

Today, air temperature is so important to us that 48% of all energy consumption in American homes is a result of cooling and heating according to the Energy Information Administration.

Development of Wine Cellar Cooling Units

Modern refrigeration technology creates the conditions required for storing and aging wine. Humidity control, as mentioned above, is one of the main differences between wine cellar cooling units and air conditioning units. State of the art controls and monitoring systems ensure precise performance and improve efficiency. With advancements in engineering and manufacturing, we have designed and developed options for every kind and size of wine storage environment.

The first company to start building and commercially selling wine cellar cooling units was Breezaire. Founded in 1985 and based in San Diego, California, Breezaire’s focus was on designing and manufacturing a wine cellar cooling unit that would have consistent design and engineered to ensure easy repairs and the seamless replacement of cooling units.

Breezaire’s CEO, Karl King, is pictured here.

The second company to join Breezaire was Wine Guardian founded by Larry Wetzel. The Wetzel family’s first wine cellar was hand-dug by Larry and a teenaged Mike under their 1820’s farmhouse foundation, utilizing the natural coolness and humidity from the earth and stone surrounding it. From that date forward, wine cellars became an essential part of their future residences. The first attempt at providing artificial cooling came during a home renovation in 1989. Larry attempted to use a home air conditioner – still the basic framework for many wine cellar cooling units today. It soon became apparent that the unit couldn’t adequately keep the recommended 55 degrees nor provide the proper humidity. It was also cumbersome and noisy. After studying what was available for purchase, the Wetzels felt they could build a better product, and soon Wine Guardian was born.

Tom Schneider is the CEO of WhisperKool. WhisperKOOL®’s began over 30 years ago with Thomas' acquisition of Vinotheque Wine Cellars. The company began manufacturing and selling luxury wine storage cabinets. They began to see the need for in-cellar evaporators specifically designed for wine cellars. Over the years, they have been continuously developed and evolved wine cellar cooling units.

One such wine cellar cooling units was the WhisperKOOL® XLT. The XLT (1995) evolved into the SCi series (2011) and, again then again, to the SC PRO (2020). WhisperKOOL® revolutionized wine cellar refrigeration by introducing the Ceiling Mount series that mounts the evaporator to the ceiling with a sleek functional purpose. Vintage Cellars and WhisperKOOL® has worked together with contractors and customers on nearly every unique and challenging installation possible. Over the many years, WhisperKOOL® has developed new models with features that allow the units to operate efficiently while addressing installation challenges.

The owners of CellarPro got their start in 2004 when they acquired Le Cache wine cabinets, which was installing Breezaire WKCE 1060 and 2200 cooling units in its cabinets.

Although Breezaire was one of the largest companies in the cooling unit industry at that time, Le Cache struggled because it wanted the quality and innovation of its cooling units to match the quality of its cabinets. Therefore, after several years, Le Cache decided to design and make their own cooling units under the CellarPro brand. Out of the box, these units offered upgrades such as digital display and controls, humidity control, coated evaporator coils, interchangeable vent configurations and advanced TXV valves for superior performance in hot temperature conditions.

After successfully launching its 1800 Series cooling units for wine cabinets, CellarPro expanded its product line, both in terms of BTUH output as well as types of equipment, using the same guiding principles to develop its new products: namely, innovation, quality, transparency and dependability.

Today, CellarPro offers the most advanced line of self-contained, ductless, ducted and split refrigeration systems.

Back to Top

Modern Wine Cellar Cooling Units

Wine Cellar Cooling Units have come a long way since the days of jerry rigging air conditioners to keep wine cool. Today there are different types of wine cellar cooling units for different types of wine cellars, rooms, wine cabinets, types of installations, different capacities, various aesthetics factors, and a wide range of costs.

Types of cooling units

The first taxonomy to consider for wine cooling systems is the type of design with which a cooling system has been engineered. There are three major types of cooling systems:

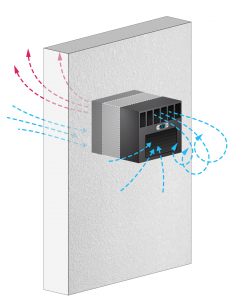

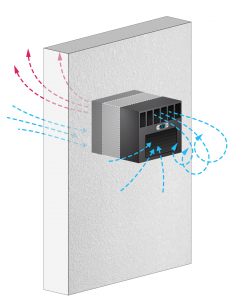

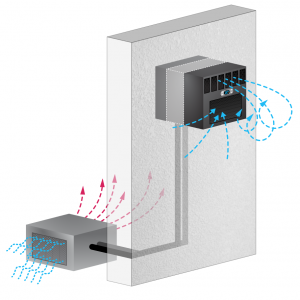

Self Contained Wine Cellar Cooling Units

As their name suggests, Self Contained Wine Cellar Cooling Units, including Through the wall wine cellar cooling units, have everything required in one self-contained system. They are usually through-the-wall units that work like a traditional through-the-wall (or window) air conditioner. This type of system is typically less expensive and you can often install them yourself for further savings.

- All the equipment in one unit

- Economical - Price range: $ 1K-5K

- Easy to install

Affordability and ease of installation make these units a popular choice, but there are some limitations.

Exhaust and Venting

Hot air exhaust is a key consideration with self-contained systems: They require an adjoining room/space where the hot air can be vented directly through the wall, so there can be potential issues with where to vent/exhaust this hot air from the backside of a through-the-wall system.

On the other hand, interior venting can be noisy and hot air (80-100 F) will be blowing into your house consistently. It isn’t advisable to vent into an adjacent bedroom for example, or into a garage, because then you are most likely penetrating a firewall and that could impact your homeowner's insurance or warranty. A mechanical room would be the ideal place for an interior exhaust vent.

Hot air can also be ducted on the backside of these self-contained systems up to 25 feet away, but it will probably look rather industrial and unattractive in a domestic setting. It is important to know that if you add any non-factory attachments, like ducting, to these units, you will void the warranty.

This kind of system can also be noisy which needs to be taken into account in planning and installation.

Temperature Differential

Not all of them can be vented to the outside which is preferred. For instance, Breezaire units have a 25 degree temperature differential. If you're cooling down the wine cellar to 55 degrees, it can't get above 75 or 80 outside or wherever you are venting. This can be a serious limitation in some settings.

There are some cooling units that have a 55 degree temperature differential, and they're made to vent to the outside. These units can handle exterior temperatures up to 110 degrees assuming you're cooling down the wine cellar to 55-57 degrees which is the prime aging temperature for wine.

BTUs

The highest BTU offered with through the wall units is 8,000 BTUs that will cover up to 2,000 cubic feet of cellar space. There are also self-contained fully ducted systems (see Fully Ducted entry below) that have greater BTU capacity and can work well for larger spaces.

Service and Maintenance

Additionally, self-contained systems cannot be serviced on site and usually have to go back to the manufacturer for any repairs. This can be a time consuming and expensive process and all the while you don’t have cooling for your cellar unless you have a back-up in place.

As long as the various potential issues are known and addressed ahead of time, self-contained cooling units can be an affordable and effective choice for your wine cellar.

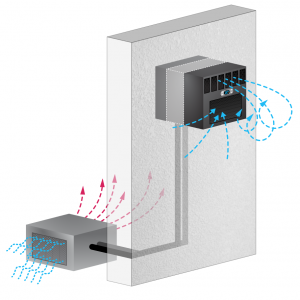

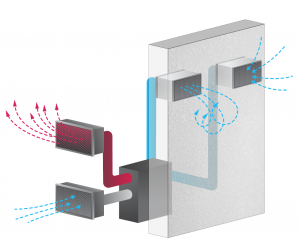

Split Systems Wine Cellar Cooling Units

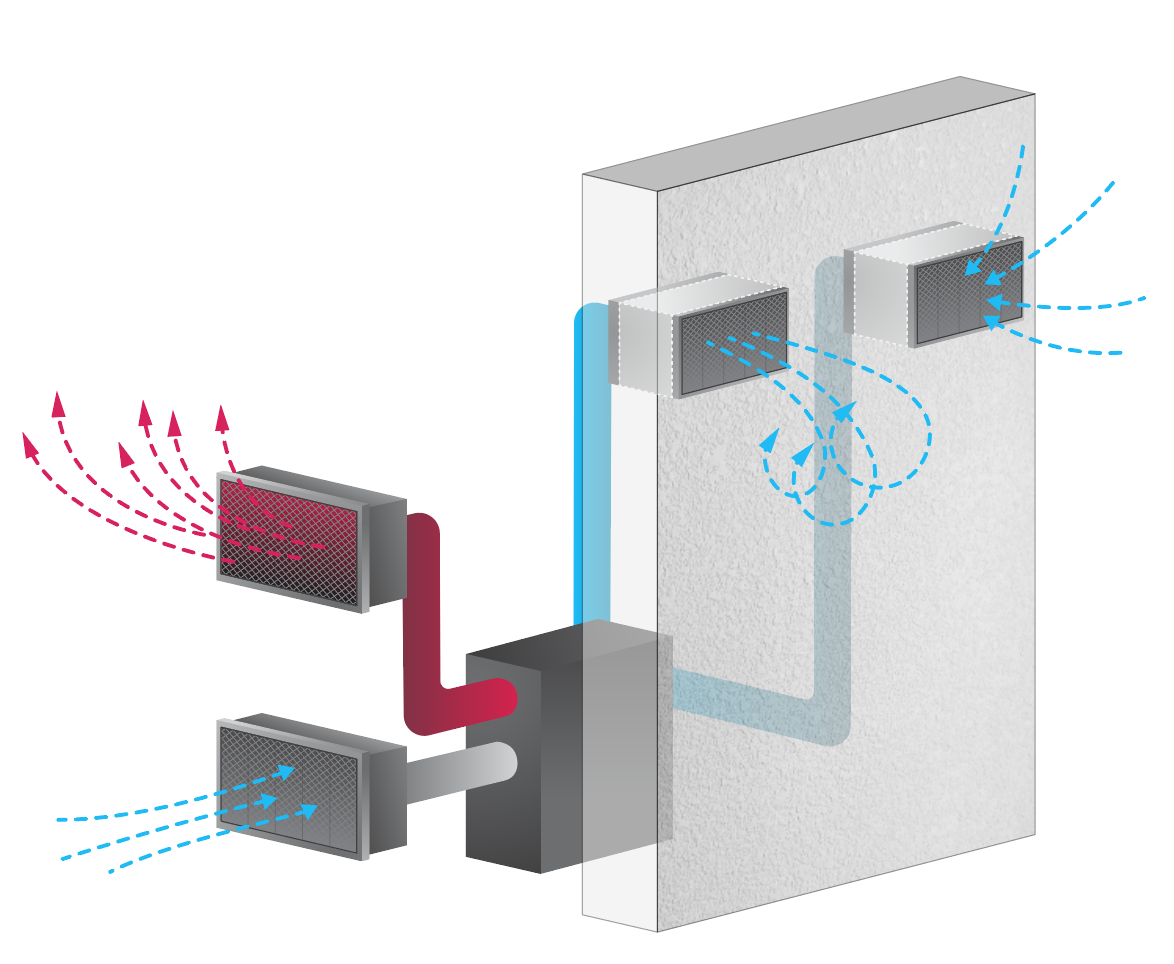

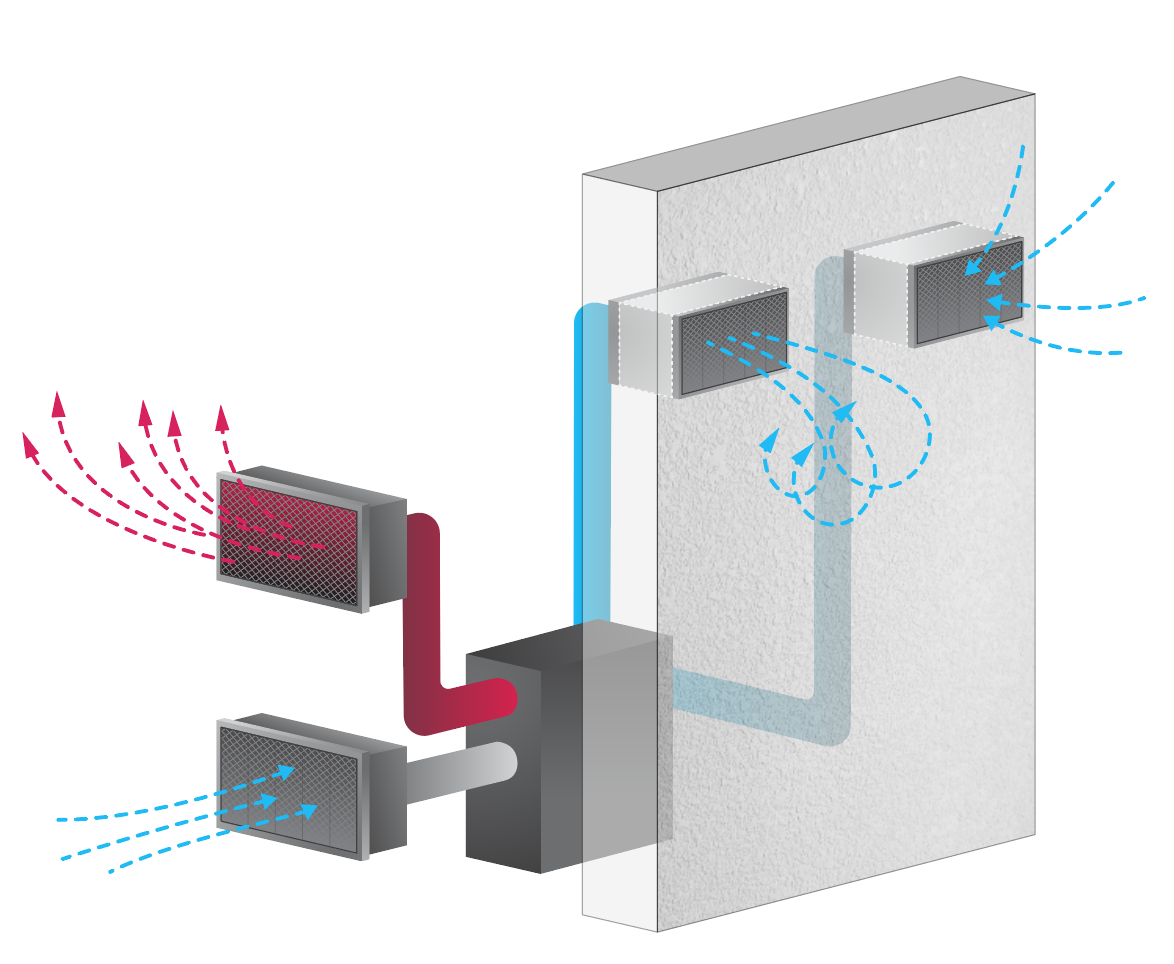

Split Systems Wine Cellar Cooling Units are a great option to use with wine cellars whenever possible. Split systems are a commercial quality option that does not require you to have an adjoining room/space for the heat to exit. With Split System cooling units, the condenser is separated from the evaporator coil and fan that provide the actual cooling to the cellar. The two are connected by a refrigerant line and there is no ducting involved. The condenser, with its noise, vibration, and heat output is placed outside and away from the wine cellar where it will have less impact on the home or business.

- Condenser is separate from the Evaporator Fan/Coil

- Maintenance and operation can impact the wine collection less

- Longer lifespan

- More powerful units available

- Price range: 9K-$15K

- Requires a licensed HVAC contractor for installation and maintenance (semi-annual)

More Powerful

Split systems are typically more powerful than self-contained units. There are commercial grade split systems that have a maximum cooling power of 30,000 - 50,000 BTUs and have longer lifespans. With much more cooling power, these wine cellar cooling units are also more expensive – costing in the $9K-$15K range.

On the plus side, you're going to have a wide variety of options for integrating split systems into the design of the wine cellar. Ideally you want to design the wine cellar and the wine racking around the split system rather than vice versa.

Highly Versatile

There are many different units, size options and configurations offering great versatility. You can always find ways to hide the unit, either recessing it in the ceiling or integrating it into the racking. You can also choose to display the unit.

Service and Maintenance

Split systems do require an HVAC contractor for installation and maintenance. The fact that they can be maintained, repaired and serviced on site is a big advantage. It is best practice to have your cooling system serviced every six months.

Note: With split systems, you also have to take into consideration where you're located. If you're near the coast, the salt air can damage the compressor quite quickly (within six months in some cases) - you get pinholes in the compressor and leak refrigerant. In a beach community, or even close to the coast, the coils should be coated for added protection. Pouring alkaline water on the compressor coils, usually every month, also helps prevent corrosion.

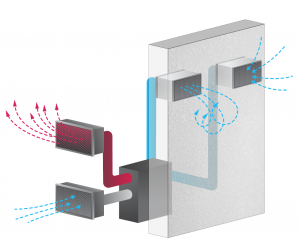

Fully Ducted Wine Cellar Cooling Units

Fully ducted wine cellar cooling units connect the two parts of the cooling equipment (condenser - outside and evaporator, coil/fan - inside) with ductwork to move the air around the system just like a Heating and AC System in your home or business. Fully Ducted Wine Cellar Cooling Units can be Self Contained Ducted Wine Cellar Cooling Units or Split System Ducted Wine Cellar Cooling Units.

- Can be a Split system or Self-contained

- System connects to Wine Cellar with ducting to keep cooling unit separated from Wine cellar

- Cleanest look – nothing but registers visible

- Require a licensed HVAC contractor for installation and maintenance

- Price range: $3.5K-7K

Less is More

These systems provide the cleanest look for a wine cellar. If you have a designer or a homeowner that does not want to see anything in the wine cellar except for registers, similar to an HVAC system in your house, then the best choice, using either a split ducted system or a fully ducted system.

Fully Ducted systems are more expensive than through-the-wall units and they are in the same price range as split systems of similar cooling power. The price of a fully ducted cooling unit without the installation cost ranges from $3,500 to $7,000.

Self installation is possible as long as the system comes charged with refrigerant.

Back to Top

Additional Types of Wine Cellar Cooling Units Categorization

Additional methods for categorizing cooling units include sizes of cellars & bottle count for which a cooling unit is suited to cool, mounting options, BTU, and lastly, storage type - whether the cooling system is meant for residential or commercial use.

Wine Cellar Cooling Units by "Size, Type of Cellars, & Bottle Count"

There are wine cellar cooling units for wine storage cabinets, walk-in wine rooms, and custom wine cellars. Wine Cellar Cooling Units designed for wine storage cabinets are usually smaller to fit in a wine cabinet and leave more space for wine storage. Wine Cellar Cooling Units designed for walk-in wine rooms follow suite on saving space, however can afford to be a little bigger since there is more space and tend to have a little more cooling power as they are required to cool a large space. Wine Cellar Cooling Units for wine storage cabinets and walk-in wine rooms tend to also be self contained wine cooling units.

All the other types of Wine Cellar Cooling Units are designed for custom wine cellars and wine rooms. There are many factors that might restrict or complicate the design of a wine storage space. We cover those factors further down in this article in Choosing Wine Cellar Cooling Units.

Wine Cellar Cooling Units by "Mounting Types"

Wine cellar cooling units have a number of mounting types, depending on the type of cooling unit. The different mounting types that are possible include through-the-wall, ceiling mounted, wall mounted, floor mounted, above the door, horizontal and vertical.

Wine Cellar Cooling Units by "Application Type"

Wine Cooling Systems can also be categorized as Residential Wine Cellar Cooling Units and Commercial Wine Cellar Cooling Units. Residential Cooling Units are typically smaller in size and have less cooling capacity while Commercial Cooling Systems are typically larger in size and have more cooling capacity. There are other subtle, but important differences between residential and commercial wine cooling systems depending on the manufacturer and design, but size and capacity are the most notable.

Wine Cellar Cooling Units by "BTUs"

We have already mentioned that BTUs are used for measuring cooling power. They are also used to classify cooling units. Typically, wine cooling systems with less BTUs are best suited for homes while wine cooling systems with more BTUs are best suited for commercial uses.

Back to Top

Features of Wine Cellar Cooling Units

There are many different features of wine cooling systems that range from manufacturer to manufacturer. Below is a collective table of all of the features available from different manufacturers.

Features of Wine Cellar Cooling Units

Name & Description

Options

The design for which the wine cellar cooling unit has been designed.

- Self-contained

- Split

- Ducted

Allows various locations from which the power cord exits the cooling unit.

- Out the front

- Out the back

Allows various locations for exhaust outlets on the cooling unit.

- Out the front

- Out the back

Temperature Control / Monitoring Types

There are many options for temperature control and monitoring that measure a number of variables including temperature, humidity, power, wine inventory, bottle ages, and more.

- Digital Thermostat

- Remote Control Thermostat

- Bottle probes

- Wireless / Remote Sensors

- Phone Apps

- Temp differential

Wine cooling systems are designed for different application types, residential for a home or commercial for restaurants or other types of businesses.

Wine cooling systems are designed for different purposes.

- Cellar for collector

- Cellar for visual impact

- Cellar for restaurant / serving wine

- Cellar for aging

Wine cooling systems are designed for different types of storage space.

- Wine Cellar

- Walk-in Room

- Wine Cabinet or Wine Refrigerator

Wine cooling systems are designed to be installed and positioned in various ways in and near wine storage spaces.

- Ceiling (Recessed)

- Ceiling (Surface mount)

- Wall

- Through-the-wall

- Over the Door

- On the floor

- Vertical

- Horizontal

Wine cellar cooling units can have different types of Fans and Coils for cooling.

- Dimensions (Width, Height, Depth)

- Cooling Power (BTUs - British Thermal Units)

- Fan type (Multi-Directional, High Angle, Adjustable)

The Condenser Unit transfers heat into a refrigerant by pressurizing gas into a liquid.

- Dimensions (Width, Height, Depth)

- Coil Coating

- Vibration level

- Noise Level

Condenser Heat Exchange Type

Type of Heat Exchange Condensate Management/Removal

An added unit to control humidity and prevent drying of wine corks

- Built in

- External/stand-alone

Allows various locations from which the drain line exits the cooling unit.

- Line to Sink

- Line to Plumbing

- Line to Evaporator (1/2 inch PVC)

Cooling units are designed to operate in and manage various temperature ranges including extremely cold and extreme heat.

- Target/Ideal Functioning Temperature

- Extreme Heat

- Extreme Cold

Various external chassis are available to hold the different parts of wine cooling systems

Various options are available to move heat and cold through the wine cooling system

- Ducted (Air cooling)

- Ductless (Liquid cooling)

- Extra Ducting Footage (Default is 25 feet)

Different types and outlets and connections to distribute air are available for wine cellar cooling units

- Paintable Grilles

- Extra End Point Grills

- Extra Plenums

Some wine cellar cooling units are easier than others to install with some requiring a HVAC professional

- Easy Self-Installation

- License HVAC Contractor Needed

- Flexible installation options

Different types of lights are available on some cooling units to make the wine cellar cooling unit look cool and some lighting is meant to kill certain types of microbes

Serving Temperature Cooling Option

This option allows cooling units to control to an extended temperature range from 42°F to 64°F (5°C to 18°C) for storage spaces where one plans on serving wine to friends or customers

Manufacturers design and build wine cellar cooling units and have been able to collect data on the lifetime of their cooling units

- This varies from manufacturer to manufacturer, however the average lifetime one can expect out of a wine cellar cooling unit is from 5 to 7 years.

- If the unit is outside, weather plays a role in the lifetime of a wine cooling unit.

- Depending on the manufacturer and cooling unit model, some cooling units may be corrosion resistant.

Different Manufacturers include warranties on their wine cellar cooling units

- Depending on the manufacturer to this can range from 1 to 5 years depending with varying levels of warranty coverage.

- Depending on the manufacturer additional warranties may be available for purchase.

Back to Top

Choosing Wine Cellar Cooling Units

When deciding on which wine cooling system is the best cooling system for a wine storage space, there are several types of factors to consider. These factors are indoor variables of the wine storage space, outdoor variables of the wine storage space, and the qualities of the design and manufacture of various brands from which you have to choose when buying a wine cooling system.

Indoor variables for choosing a wine cellar cooling unit

Placement of the wine cellar in the home or business affects both the design and the choice of cooling unit. There are a number of variables inside and outside your home or building that play a role in the design of your cellar.

The following are indoor variables that can have an effect on your wine cellar design and build.

Size

The size of the space you want to dedicate to your wine cellar plays a significant role in the design and build of your wine cellar. Size is measured in cubic footage of the space. Another measurement related to space is the number of bottles to be stored.

Walk-in Wine Rooms - If a suitable stand-alone space is not ideal for a custom wine cellar and you have enough space, another good option is a Walk-in Wine Room.

Walk-in Wine Rooms are an excellent choice if none of the other options described above are a good fit for your particular situation. Stand alone walk-in wine cellars are convenient, attractive and relatively affordable. The popular Vintage Series Wine Cabinets, for example, features an oak exterior and mahogany interior, with heart redwood racking and a quality Breezaire cooling unit. Sizes range from 900 to 2,600 bottles, allowing you to age your collection in an environment comparable to the finest custom wine cellars, at a reasonable price point.

An added benefit is these Walk-in Wine Rooms are prefabricated and can be disassembled in case you move your home or place of business and then set back up in a new location.

Refrigerated Wine Cabinets - If a suitable stand-alone space is not ideal for a custom wine cellar and you do not have enough space, a wide selection of refrigerated Wine Cabinets are available.

Refrigerated Wine Cabinets are an excellent choice if you do not have enough space and still want the benefits of a Walk-in Wine Room. Some of the Wine cabinet brands that we carry are Vintage Series, Le Cache, and Transtherm. Depending on the size of the wine cabinet or wine refrigerator, it can be small enough to fit under your kitchen counter while two door cabinets can be as large as a to door closet. Depending on the sizes of your bottles and your shelving configurations, wine cabinets can typically hold 40 - 400 bottles. These storage options offer less storage space but also a lower cost for your wine storage.

Structural Walls - “Middle of Structure” vs. External Walls

Whether the walls that make up the exterior of the wine cellar are “Middle of Structure” walls or external walls plays a part in affecting the design and build of your wine cellar.

Cooling Unit Installation -Warm air created by the cooling unit needs to be vented away from the cellar so whether there is an outside wall or an adjoining space will affect design plus the choice of unit and installation.

Cooling Unit Limitations - Walls can also play a part in the placement of the wine cellar cooling unit and which cooling units can be used in a particular space.

Ducting Requirements - If the cellar is in the middle of the house you also have to take into account what's already in place, like air conditioning ducts, water lines and electrical wiring, which are usually hidden behind the walls.

Drainage Requirements - It is also important to consider where the drain line from the unit will connect, such as tying into existing plumbing or floor sink for draining water that is created in the cooling process.

"Existing Building" or "Adding To"

Similar to structural walls, another key question is whether you are designing a cellar into a house/business that’s being built or adding one to an existing structure is another important factor with all the same considerations you have with structural walls: Cooling Unit Installation and Limitations, and Ducting and Drainage Requirements.

Adjoining Spaces

The uses and purposes of rooms and spaces around the space you have dedicated for your new wine cellar play a factor in the design and build of your wine cellar.

Ventibility - Are the adjoining spaces vent-able spaces if needed? Ceilings, adjacent rooms, and mechanical rooms and or garages are spaces to which can be vented.

Other Building Variables

The location of your building management systems and pieces of equipment from other systems within your building will have an impact on the design and build of your wine cellar. These systems include but are not limited to:

- Heating/cooling ducts

- Hot water lines

- Supply ducts

- Central heating unit

- Electrical wiring and boxes

- Water sources

Outdoor variables for choosing a wine cellar cooling unit

Outdoor variables can have an effect on the wine cellar cooling unit requirements in your home or place of business. The following are outdoor variables that can have an affect on your wine cellar design and build.

Local climate / Sun direction

Local climate and sun direction can play a significant role in the indoor temperatures of your wine cellar. The local high and low temperatures of your local area, plus daily and seasonal temperature swings are critical factors to consider . The closer the temperature outside of your building stays to the desired temperature for wine storage , the less cooling will be needed to maintain the ideal environment for your wine cellar.

City ordinances

Like domestic, or commercial HVAC, wine cellar cooling units make noise, which can be quite sustained day and night. Many cities and HOAs have noise ordinances that you need to be aware of prior to installation. In some situations, the units also need to be hidden from view.

Noise mitigation

The only thing that can really be done to mitigate noise from an outdoor compressor is to build a fence around it. This hides the compressor unit from view and slightly dampens the noise created by the unit.

Back to Top

Wine Cellar Cooling Units Brands

There are several different brands in the Wine Cooling Systems market. Each brand has its own focus and specialty. Along with a general summary about the brand and wine cellar cooling units, we have provided some considerations about each brand to help potential wine cellar cooling unit buyers have a better understanding about each brand and make a decision about which wine cellar cooling unit is best for their wine storage needs.

All the wine cellar cooling units highlighted here are designed and manufactured in the USA.

Wine Guardian

Regardless of the size or type of the wine cellar, Wine Guardian cooling systems have been consistently relied upon to deliver superior performance in wine cellar temperature and humidity control, ensuring the perfect conditions for your wine collection. Their specialty is fully ducted and ducted systems suitable for almost any wine cellar configuration.

The company founders, father and son, Larry and Mike Wetzel, have spent most of their careers designing and manufacturing specialty air conditioning and refrigeration equipment. In business since 1998 Wine Guardian had been building ducted wine cellar cooling systems longer than any other manufacturer.

Vintage Cellars is a trusted and authorized distributor of Wine Guardian wine cooling systems.

Shop Vintage Cellars for Wine Guardian Wine Cellar Cooling Units

Breezaire

Breezaire’s forward thinking engineered and well-designed cellar cooling units have been manufactured in the U.S.A. since 1985. Breezaire’s commitment to their products and their customers is demonstrated by their ability to repair any unit they have ever manufactured so there is no redundancy. Breezaire offers several entry-level through-the-wall units and some split systems options. These are the most straightforward and economical cooling systems available on the market.

Shop Vintage Cellars for Breezaire Wine Cellar Cooling Units

Cellarpro

CellarPro products have been designed and built for commercial wine cellar cooling since 2008. The rewards of their research and development are clear as empirical test data shows CellarPro wine cellar cooling units out perform the competition on every level.

Cellar Pro offers every type of cooling unit you can imagine, from cabinets and through-the-wall systems, to split ducted, split, fully ducted, and water-cooled.

Every single CellarPro unit uses E-coating to combat any erosion and also has an independent fan control. Commercial-grade Electrofin coating protects the evaporator coils from leaks, corrosion, and pollutants.

In addition, Cellarpro offers the best and longest warranty in the industry, covering parts and repair on most units for up to 5 years.

Shop Vintage Cellars for Cellarpro Wine Cellar Cooling Units

WhisperKool

With over 500,000 units sold, WhisperKOOL has been designing and building Innovative solutions for optimal wine storage and display for more than 30 years. Perfect for the client that wants a more compact unit featuring elegant, modern design.

WhisperKool is recognized internationally as a leader in professional wine cellar cooling systems with features like liquid probe thermometers that monitor the actual temperature inside your bottles, sleek modern design, and innovative features like UV lighting.

WhisperKOOL systems are suitable for cellars of any size, offering a wide selection of wine cooling systems including through-the-wall, split, split ducted, fully ducted options for their units.

Shop Vintage Cellars for WhisperKool Wine Cellar Cooling Units

CellarCool

With over twenty years of experience, CellarCool is an industry leader in the manufacture of wine cellar cooling units. CellarCool offers economical wine cooling systems designed for cellar enthusiasts who are on a budget. CellarCool units achieve optimal results by cooling the air slowly, cycling down the temperature while maintaining humidity between 50% and 70% in properly prepared wine cellars. With a 30 degree temperature differential CellarCool cooling units are recommended for indoor installations. They are designed to be installed into any mounting location.

All CellarCool wine cellar cooling units are shipped factory direct to their customers and feature an excellent 2 year warranty and preventive maintenance program.

Shop Vintage Cellars for CellarCool Wine Cellar Cooling Units

Commercial Grade Split Systems

Vintage Cellars offers innovative commercial split systems to meet every need. This includes wine cellar cooling systems for restaurant wine bars, wine rooms, and commercial wine storage areas. Our commercial split system wine cellar cooling units are fully customizable and range in size from 1200 BTU to 40,000 BTU allowing us to outfit anything from a home wine cabinet to a commercial wine storage area, and every wine cellar in between.

Shop Vintage Cellars for Commercial Grade Split Systems Wine Cellar Cooling Units

Back to Top

Wine Cellar Cooling Units Glossary

We have a list of terms related to Wine Cellar Cooling Units to help you with wine cooling system related terms. For more, see our full list of wine storage terms.

Humidity

A relative humidity of between 50% and 70% is ideal for aging wine. A too-humid environment will cause mold to form on the cork, possibly contaminating the wine. Not enough humidity, and the cork will dry out and crack. A too-dry environment will also cause wine to rapidly evaporate from the bottle, creating a vacuum that sucks in oxygen-rich air. Any of these conditions will result in a bottle that is "corked"--tainted due to cork failure. Humidity can be added using an integrated humidifier such as that available in CellarPro cooling systems, a separate humidifier such as the Wine Guardian through the wall humidifier or with decorative humidifier fountains.

Insulation

Insulation is important to wine cellars and wine cabinets. Made of materials that resist the transfer of heat, insulation keeps your cold things cold and your warm things warm. Heavy-duty insulation may be required in wine cellars to maintain proper temperatures. Skimping on the insulation phase will lead to overworked and inefficient cooling systems. Money spent on insulation is money saved down the line. Foam board insulation is commonly used in wine cellar construction.

Split System Cooling

Split system wine cellar cooling units are commonly used when placing the entirely of an evaporator/condenser system inside the building is undesirable. They are both quiet and unobtrusive, because only the intake and outtake grills will be visible in your cellar and the condenser is situated outside your cellar for noise reduction. The first component of split system wine cellar cooling units is an evaporator coil installed in the wine room or wine cellar. The evaporator coil circulates cold air and controls the humidity. The second component of split system wine cellar cooling units includes a compressor, condensing fan, and coil. This unit is installed outdoors or in an adjoining room and requires ventilation. The two sections are connected by refrigeration lines. See our split system cooling units for details and diagram.

Temperature

Wine ages best in cool temperatures--approximately 55 degrees F. A temperature of 55° is the perfect environment for the chemical reactions that result in good wine. But it's too cold to allow other, undesirable reactions that can give a wine unwanted aromas. Even a short exposure to extreme temperatures can trigger unwanted reactions and ruin the wine. Wine ages best at a temperature that is both cool and constant. Choosing the correct wine cellar cooling system or wine cabinet for your storage location will ensure proper temperatures for your collection.

Temperature Differential

This refers to the ability of a cooling or refrigeration system to deal with ambient temperatures. The temperature differential is the number of degrees higher the ambient temperature can be than the desired 55 degrees without overtaxing the unit. For example, if a cooling unit has a temperature differential of 40 degrees, the temperature outside the cooled space should not be more than 95 degrees if one wishes to maintain a 55 degree storage temperature for their wine.

Thermoelectric Cooling

A method of cooling that uses the Peltier effect to provide cooling. Thermoelectric wine coolers are very energy-efficient and produce no vibration, so as to leave sediment undisturbed. See also: Full article on Thermoelectric vs Vapor Compression.

Vapor Barrier

A vapor barrier is a moisture-proof layer that is added during the insulation phase of construction. Some insulation incorporates a vapor barrier. The barrier must be installed on the "warm side" of the insulation (ie outside your wine cellar) to prevent condensation. It is common to install a vapor barrier by wrapping the room in plastic during the insulation phase. A vapor barrier is very important to prevent moisture damage to your wine cellar or surrounding areas. See also: insulation.

Vapor Compression Cooling

Vapor compression cooling works just like your kitchen refrigerator. A compressor pushes the molecules of the refrigerant together, which causes a temperature increase, then cools the refrigerant vapor slightly without allowing it to expand. Then it is expanded in the evaporator, becoming extremely cold and cooling the air that is blown over the coils of the evaporator. Vapor compression cooling is effective but not efficient. See also: thermoelectric cooling.

Back to Top

Vintage Cellars: We are Wine Cellar Cooling Units Experts

We hope you enjoyed the Vintage Cellars Wine Cellar Cooling Units Ultimate Guide. If you have any questions or suggestions please feel free to reach contact us.

Here to Help You with your Custom Wine Cellar

With more than 30 years of building Custom Wine Cellars, we are experts in designing and building Custom Wine Cellars from soup to nuts. We help clients nationwide and would be glad to give you a free design for your custom wine cellar.