CellarPro Recessed Ceiling Mount 1/3 Ton AH3000Scmr-ECX

CellarPro Recessed Ceiling Mount 1/3 Ton AH3000Scmr-ECX

CellarPro Ducted Ceiling Mount Recessed AH3000Scmr-ECX (P/N 36912). NOW WITH ENERGY-EFFICIENT EC FANS! CellarPro engineered the Ducted Ceiling Mount Mini-Split AH3000Scmr-ECX cooling system to provide maximum cooling power and adjustable humidity control with a ceiling-mounted evaporator that can be recessed in the ceiling and, therefore, hidden from view. The condensing unit can be ducted, and the evaporator includes a variable-speed fan with a low setting for quieter operation and a high setting for maximum power.

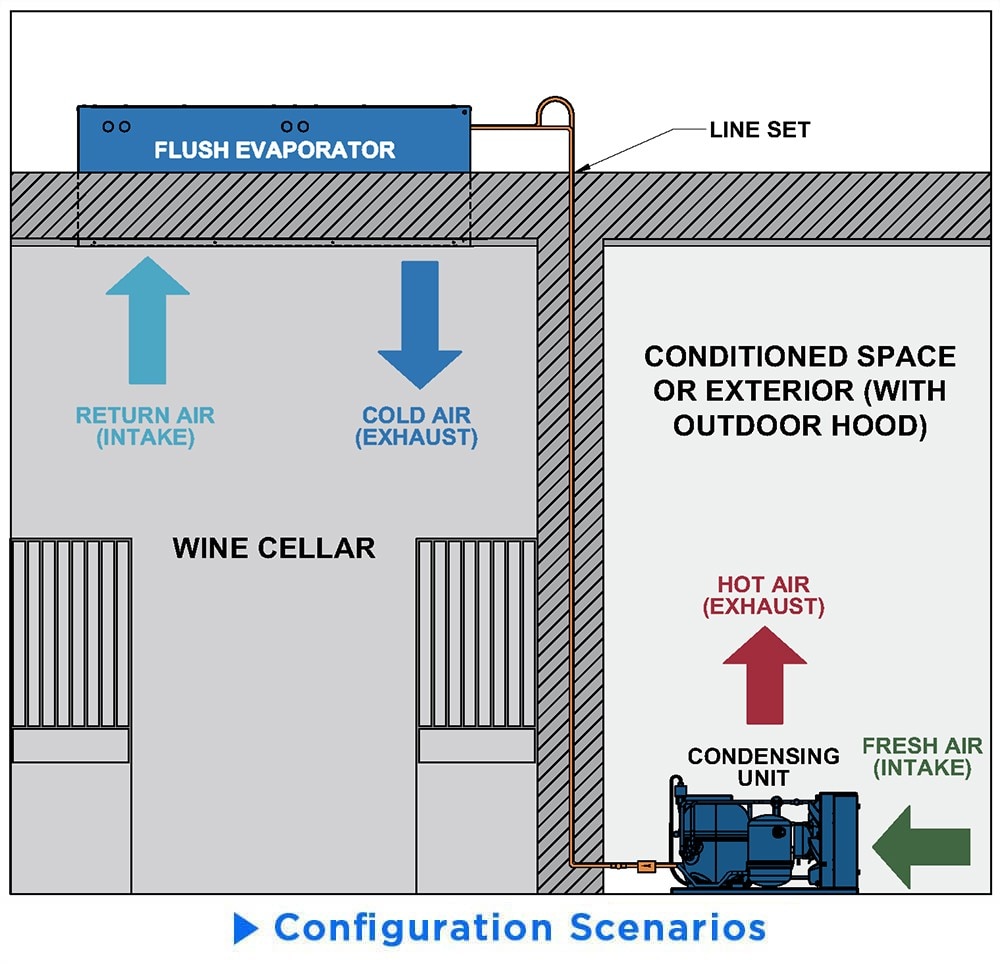

All air-cooled refrigeration equipment requires fresh air intake to dissipate the heat generated by the cooling unit. The condensing unit must be installed outside the cellar in a location that provides ample space and access to fresh air.

Features

- Now with energy-efficient EC Fans on the cold side, save $72.04 in annual energy costs vs AC fans (assumes 75% runtime and $0.15/kWh)

- This unit is designed to separate the heat and noise from the condensing unit from interior living spaces

- Our Evaporators are built with high-output centrifugal fans, which include variable speed settings for your choice of maximum cooling power at the high fan speed or quieter operation (51 decibels) at the low fan speed.

- The Condensing Unit can be ducted to indoor or outdoors environments ranging from -20 to 110F.

- Adjustable humidity control combines a high-output compressor with flexible fan cycles to maintain a recommended level of moisture inside your cellar.

- Extra-large coils generate maximum cooling power inside the cellar.

- Excess condensate is managed through an internal integrated condensate pump and a 1/4" drain line that exits from a choice of knockouts in the evaporator. The pump has automatic overflow protection.

- Commercial-grade Electrofin coating protects the evaporator coils from leaks and corrosion.

- Remote LED display panel and digital programmable controls include 20 feet of wiring and can be mounted inside or outside the cellar.

- Quick-chill mode and auto-defrost cycle provide convenient solutions to common cellar needs.

- Temperature set point range is 47F to 62F when the cooling unit is properly sized.

- Unit operates with minimal vibrations and less noise than comparable units from competitors.

- Audible and visual alarms and a maintenance-needed indicator protect the cooling unit and the wine cellar.

- Multiple knockouts and access points ensure easy installation.

- Common dedicated 15-amp circuit is required to power the unit.

- Factory-installed Expansion Valve and Liquid Line Solenoid Valve (optional) ensure maximum operating precision and range.

- Refrigerant access valve provides access to the internal components for servicing and repair.

- Sight Glass and Liquid Line Filter/Drier are included for easy installation and maintenance.

- Oversized Receiver allows long line sets up to 100 equivalent feet and up to 30 vertical feet.

- The auto reset high-pressure switch protects the system by interrupting power to the compressor when system pressure is too high.

- Evaporator and Condensing Units are factory-pressurized and shipped with dry nitrogen to ensure leak-free installation.

- CellarPro's 2-Year/5-Year Warranty, the most thorough in the industry, protects the unit against manufacturing defects.

- An optional Extended Warranty (P/N 31489) is available for additional protection.

- ETL Tested and Certified to rigorous UL Standards for safety.

Specifications

Brand: CellarPro

UPC: 077757369124

Size:

Evaporator Unit Dimensions:

- 60 lbs

- 35 3/4w x 14 1/4d x 12 7/8h (in)

Condensing Unit Dimensions:

- 111 lbs

- 18 1/2w x 18 1/2d x 19 1/4h (in)

Power/Rating:

- Common dedicated 15-amp circuit is required to power the unit.

- Startup: 30.0 Amps

- Unit Amp Rating: 7.5 Amps (high fan speed)

- Total Watts: 555 (med fan speed)

BTUH @ 55F / Evaporator Decibels

- Low Fan Speed: 2468 BTUH / 51 dbA

- Medium Fan Speed: 2854 BTUH / 55 dbA

- High Fan Speed: 2980 / 63 dbA

- 1/3 Ton Nominal

Condensing Unit Decibels

- Low Fan Speed, Ducted / Non-Ducted: 43 dbA / 56 dbA

- Med Fan Speed, Ducted / Non-Ducted: 50 dbA / 63 dbA

- High Fan Speed, Ducted / Non-Ducted: 55 dbA / 68 dbA

Upgrades

Cold-Temperature Options

- Compressor Heater (optional add-on): protects the compressor from off-cycle refrigerant migration. Select this option if your cellar will face extended cold conditions.

- Fan Cycling Switch (optional add-on): supports low-ambient operation down to 20 °F—and as low as 0 °F (valve control) or –20 °F (electronic control). Choose this upgrade for extra cold-climate reliability.

Filter & Grill Options

- Select the filter and/or duct grill option that matches your cooling unit’s specifications directly on the product page.

Maintenance Add-Ons

- Evap Fresh (optional): quarterly spray for evaporator (cold-side) coils to inhibit mold growth and extend coil life.

- Condenser Brush (optional): long-handled brush for cleaning dust and debris from condenser (hot-side) coils when no filter is used.

Remote Thermostat & Probe Options

- Networkable Thermostat (optional): Wi-Fi enabled thermostat. Includes 10 ft of wiring; add this option to monitor and control your unit remotely.

- Remote Display (optional): digital panel you can mount anywhere inside or outside the cellar. Includes 10 ft of wiring; additional wiring available at $0.50/ft.

- Bottle Probe (optional): 10-ft cord probe that overrides the unit’s built-in thermostat to measure air or liquid temperature at any point in the cellar.

- Probe extension cords (optional): choose 25 ft or 50 ft lengths to reach your ideal mounting location.

Replacement & Service

For warranty support or service coordination, please contact the manufacturer directly—let us know if you need assistance arranging an RMA or replacement unit under warranty.

Q &A

What is "Sensible BTUH"?

A: You should always use Sensible BTUH* when comparing different cooling unit brands and when sizing a cooling unit for your wine cellar. Every cooling unit produces a certain amount of Total BTUH, the sum of Sensible BTUH (lowers the temperature) and Latent BTUH (lowers the relative humidity). Because our goal is to cool wine cellars while preserving humidity, wine cellar cooling units should have high Sensible BTUH and low Latent BTUH. The relationship between Sensible and Latent BTUHs is known as SHR (Sensible Heat Ratio), calculated as Sensible BTUH/Total BTUH. The SHR for CellarPro cooling units is greater than 90%, which means that CellarPro units provide maximum cooling power without stripping out humidity from the cellar environment.

*CellarPro Sensible BTUHs are calculated assuming 55F cellar temperature, 60% relative humidity and 95F ambient for all units except 1800 units (85F ambient).

What's the difference between a split system and "through the wall" or "self-contained" systems?

A: Split systems are "split" into two parts: the cold side (evaporator), which is usually installed inside the cellar, and the hot side (condensing unit), which is installed away from the cellar. The benefit of having this split is that the heat and noise from the condensing unit can be located far away from living spaces where they won't interfere with day-to-day life.

Are split systems more difficult to install than self-contained systems?

A: Yes, because split systems require installation by a licensed HVAC technician (unless you are purchasing our quick-connect split system.) In contrast, self-contained units can be mounted through the wall and shipped fully charged and operational out of the box.

What's the difference between valve control and electronic control? Which is better?

A: The most significant difference between the valve and electronic control is that, with electronic control, the condensing unit receives power directly from the evaporator, whereas with valve control, the condensing unit is independently powered and turns on/off based on the solenoid valve. Valve control is more common in the industry and benefits from not having to run a power line from the evaporator to the condensing unit but cannot operate in temperatures below 0F. Electronic control offers more precision and allows the condensing unit to be placed in temperatures down to -20F (with the addition of a compressor heater and fan cycling switch.)

Can the evaporator be located remotely and ducted to/from the wine cellar?

A: Ceiling-mount evaporators are designed to be installed in the cellar's ceiling. They are not designed to be ducted.

Can I install the entire unit inside the cellar?

A: No, the condensing unit is designed to be located remotely, outside the cellar, and connected to the evaporator via copper lineset.

If I don't have sufficient space around the condensing unit, is that OK?

A: The hot side of the cooling unit generates hot air that must have sufficient space to dissipate. It also requires a source of cool, fresh air that isn't polluted by the equipment's hot air exhaust and must be from outside the wine cellar. The hot-side airflows can be ducted if sufficient space doesn't exist where the equipment is located.

Does the evaporator include flare connections, or will I need to braze the connections to the line set?

A: Flare connections are much more prone to leaks and have been phased out over the years and replaced by fully brazed connections. This is driven by the EPA and the focus on minimizing refrigerant leaks into the atmosphere.

Does the unit really need a dedicated circuit?

A: First, the background. Unlike our competitors, we build our cooling units with precision expansion valves, not cap tubes, so our cooling units aren't limited to a 30F differential between the desired cellar temperature and the ambient temperature. Cooling systems with expansion valves are much more precise than cap tubes and sensitive to low-voltage conditions, which is why our units require dedicated circuits. When we say "dedicated circuit," we mean that the circuit shouldn't have any items that require heavy draws of electricity - e.g., other appliances, vacuum cleaners, big-screen TVs, blow-dryers - on the same circuit as the cooling unit. Lighting, computers or other low-draw items should be fine on the same circuit.

Configuration

- Ducted split cooling systems are designed for ceiling installation, with the evaporator recessed above the cellar and the condensing unit located remotely.

-

Wiring Options:

- Electronic Control (single power source at the evaporator): includes a compressor heater for low-ambient operation down to 20 °F (and as low as –20 °F when paired with the fan cycling switch option).

- Solenoid Valve Control (separate power to evaporator and condensing unit): includes compressor heater for operation down to 20 °F. Recommended only for environments above 20 °F.

-

Mounting Styles:

- Flush-to-Ceiling: oversized bottom grille sits flush against the ceiling surface.

- Recessed/Protruded: standard-size grille that can be installed either recessed into or protruding below the ceiling.

-

Ducting & Filtration:

- Interchangeable collars and grilles let you tailor airflow to your layout.

- Built-in professional-grade return-air filter ensures clean operation.

- We recommend locating the fresh-air intake in a temperature-controlled space outside the cellar to avoid negative-pressure issues.

- Condensing units can be ducted up to 100 equivalent feet (50 feet per run) using 8″ ducting.

- A 10 ft temperature-sensor probe plus your choice of duct collars, indoor grilles, and blank plates are included with the system.

- Evaporator units must be kept above 32 °F at all times and remain accessible from below for service.

- All split systems must be installed and charged on-site by a qualified HVAC professional, following ASHRAE line-set guidelines.

- Units must be shipped and handled in the upright position; never operate on their side or upside down.

- Systems ship strapped to a pallet via common carrier; inside delivery is available for an additional fee.

- To activate your warranty, please complete and return the installation checklist provided with your equipment.

Additional Info

2980 SENSIBLE BTUH @ 55F.

CellarPro's AH3000Scmr-ECX Ductable Recessed Ceiling Mount split cooling system features an evaporator (1/3 Ton Nominal) that is designed to be recessed in the ceiling and a condensing unit that can be ducted. This unit is suitable for wine cellars up to 700* cubic feet in both commercial and residential wine cellars.

Performance testing shows that this unit maintains optimal cellar temperature and humidity conditions in extreme conditions up to 110F more effectively than similar units from competing brands. AH3000Scmr-ECX units use energy-efficient EC fans and are significantly quieter than comparable units from other manufacturers.

All ceiling-mount units include our remote display with 20 feet of low-voltage wiring (additional wiring available upon request) and an integrated condensate pump as standard equipment. Visit our Learning Center for data tables, performance charts, and product comparisons among different brands.

*The cellar size assumes that the cellar is constructed with a proper vapor barrier, insulation of R19 or better in all walls and ceiling (i.e., no glass or uninsulated concrete), a setpoint of 55F inside the cellar, and ambient temperatures up to 85F outside the cellar.

Our cooling units are designed to be used in properly constructed wine cellars that are adequately insulated, airtight, and sealed with a vapor barrier. In improperly constructed cellars, the cooling unit will create excess condensation, leading to damage and premature failure of your cooling unit (not covered by warranty).

Manuals & Guides

Click on one of the following links for more information:

- Spec Sheet

- Sizing Table

- Monthly Operating Cost

- Recessed Configuration Cut Sheet

- Flush Configuration Cut Sheet

- Recessed Configuration Framing Diagram

- Flush Configuration Framing Diagram

- Ducting Configurations

- Line Sizing Chart

- Configuration Options

- Wiring Diagram - Dual Power/ Valve Control

- Wiring Diagram - Single Power / Electronic Control

- Refrigerant Piping Diagram

- Refrigerant Piping Handbook

- Owner's Manual

- Installation Checklist